production

production stages

Denim is the most used, most versatile and most stylish fabric in the world. The production stages are a different journey;

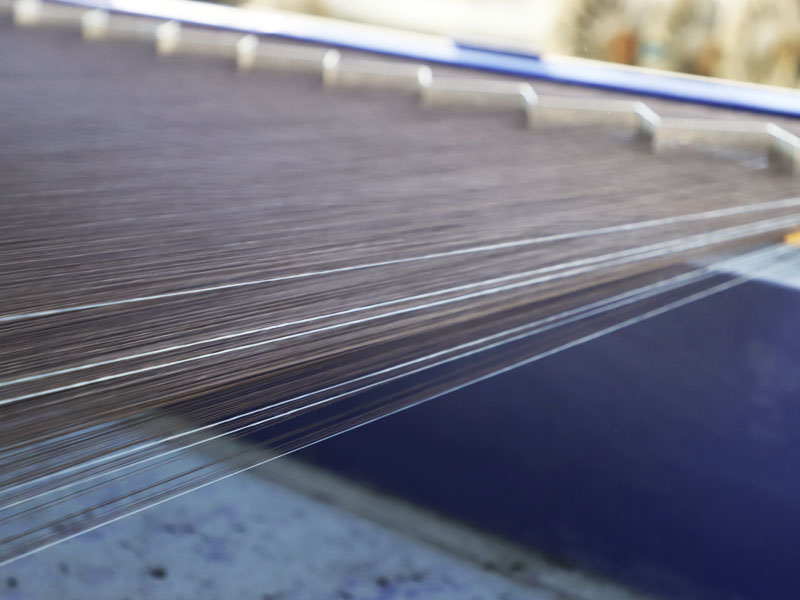

Indigo Warp (Slasher) Dyeing: In this dyeing system, warp yarns are dyed as open width form. Depending on the construction of the fabric, 12 to 16 warp beams containing 350 - 500 warp threads each are placed in front of the slasher dyeing line. Then all of the yarns in the warp beams are respectively pass through the slasher line for continuous dyeing, drying, sizing and warping processes.

Weaving: Indigo dyed warp beams are put into the weaving process. In order to realize the weaving process, the warp yarns are passed through the strengths, lamellae on the frames and finally comb teeth in accordance with the pattern report and the weaving draft is completed.

After weaving draft, weaving process starts and now denim fabric has started to form.

Finish Processes: In denim fabric production, after weaving process; finishing treatmens are applied such as burning, softening, width adjustment and sanforizing. Over / dyeing is also done at this stage.

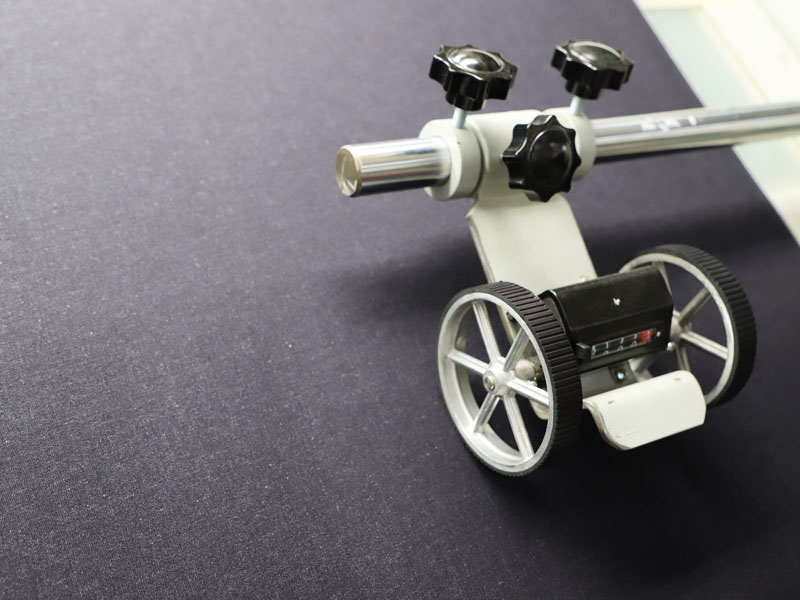

Quality Control: After finishing process all fabrics are evaluated by the quality assurance team according to the 4 point control system and ready to meet the customer with world-class packaging equipment..